Electric motors from series H2 are 2 pole asynchronous single-phase submersible motors designed to operate coupled to 4” ZDS hydraulic parts. They are made of materials suitable for contact with water, and cooling and lubrication of the thrust block and bushes are guaranteed by a mixture of water and glycol. H2 motors are equipped with a special and unique start and run capacitor, which is designed to guarantee a long-life to the motor and avoid the installation of an external control panel. They also come with a special and manually resettable built-in thermal protection, which stops the motor when overheated.

Supply cable connector is removable for quick and easy maintenance.

APPLICATIONS

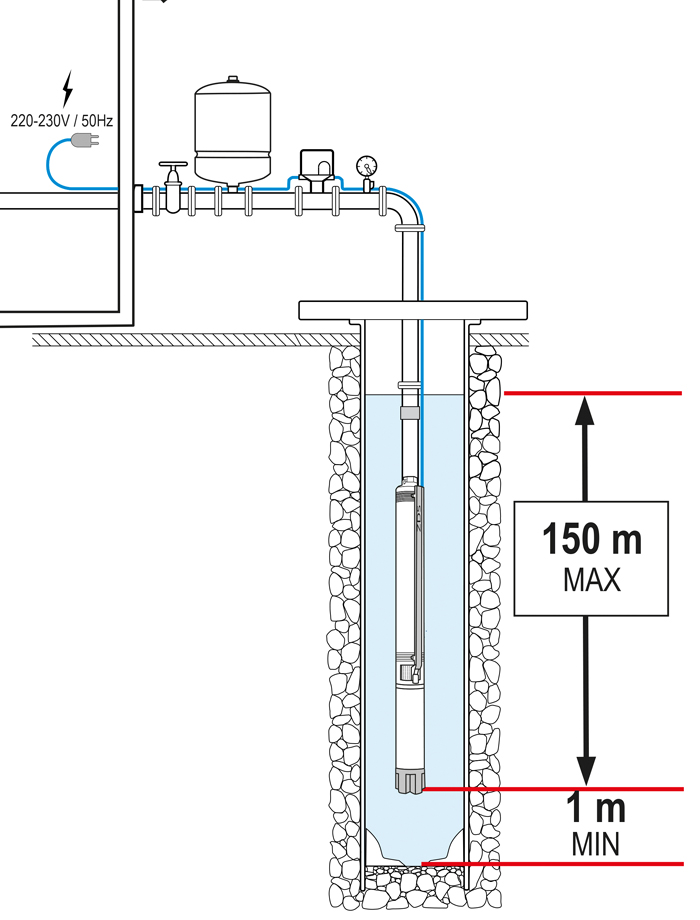

H2 water-cooled motors ensure reliable working in 4” or larger diameter wells and are designed to be used for lifting, distribution, and pressurisation of water in water systems.

H2 motors can be installed with a frequency inverter.

CHARACTERISTICS OF CONSTRUCTION

-

2 pole asynchronous 2-wire single-phase encapsulated water-cooled motor.

-

Special and long lasting integrated start and run capacitor. In case of need it can be easily replaced.

-

Axial and radial water-lubricated bearings allow for maintenance-free operation.

-

Hermetically sealed stator by 304L stainless steel flanges, internal and external casings, filled by resin to guarantee optimal cooling capacity of temperature during operation.

-

Rotor set on Kingsbury thrust block equipped with carbon clearance ring and oscillating pads in high-strength stainless steel to sustain high axial loads.

-

Pre-filled with non-contaminating antifreeze lubricant liquid.

-

Sand protection to guarantee optimal operation even with sand in the borehole.

-

Removable lead connector to make installation and maintenance easier.

-

Supply cable according to drinking water regulations (ACS), available in different lenghts.

Send us a request