Electric motors from series O3 are 2 pole asynchronous single-phase submersible motors designed to operate coupled to hydraulic parts with 4” Nema standard. Strong and reliable, they are made of materials suitable for contact with water and oil-cooled by FDA - Food Drug Administration approved dielectric fluid. O3 motors require a start and run control panel, that has to include capacitor and manual reset amperometric protection. The supply cable connector is removable for quick and easy maintenance.

APPLICATIONS

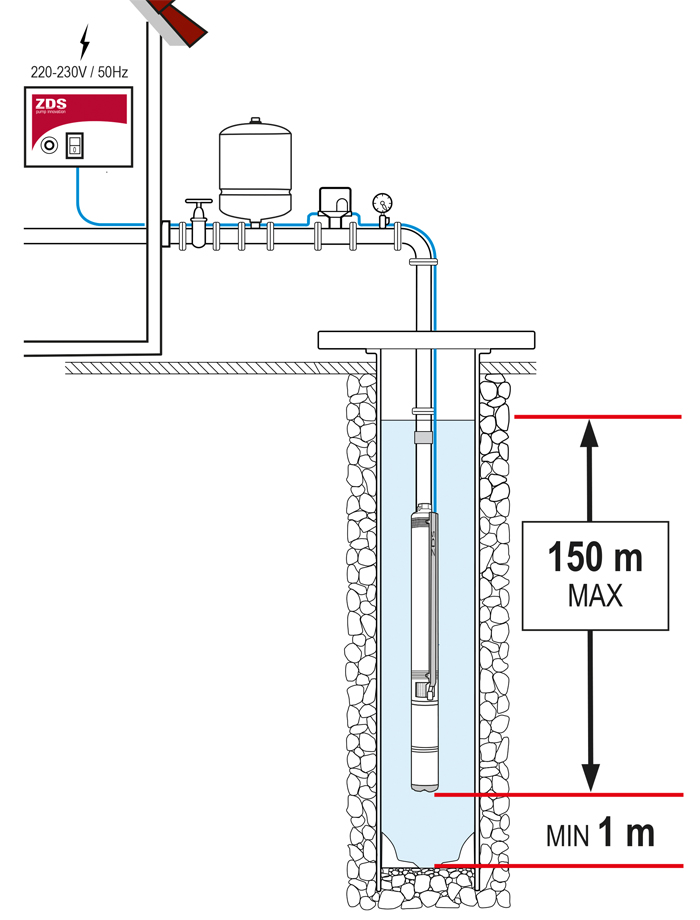

O3 oil-cooled motors ensure reliable working in 4” or larger diameter wells and are designed to be used for lifting, distribution, and pressurisation of water in water systems. O3 motors can be installed with a frequency inverter.

CHARACTERISTICS OF CONSTRUCTION

- 2 pole asynchronous single-phase PSC oil-cooled motor.

- Rewindable stator and rotor immersed in dielectric fluid (FDA approved).

- Oversized axial and radial oil-lubricated bearings to guarantee longer life to the motor.

- The pressure compensation inside the motor is ensured by a special internal diaphragm.

- Sand protection to guarantee optimal operation even with sand in the borehole.

- Motor bottom cover for extra protection and safety.

- Removable lead connector to make installation and maintenance easier.

- Supply cable according to drinking water regulations (ACS), available in different lenghts.

Send us a request